Quick Details

Structure:

Deep Groove

Type:

Ball

Applicable Industries:

Manufacturing Plant, Machinery Repair Shops

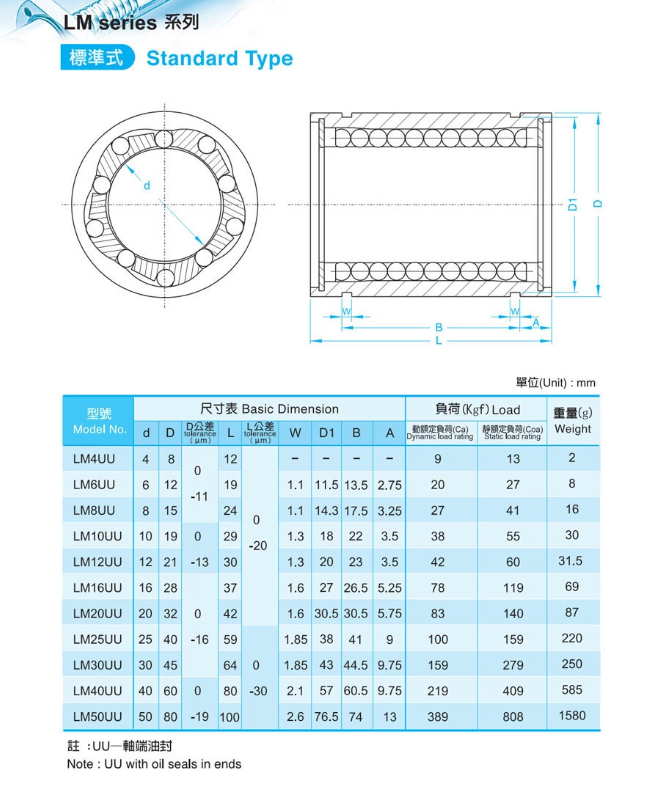

Bore Size:

4 - 50 mm

Model Number:

LM, Single/Double Nut Ball Screw

Place of Origin:

Shandong, China

Product name:

China quality supplier long type 12mm linear ball bearing CNC parts

Manufacturing Process:

Milled Thread

Material:

GCr15, Bearing Stee

Brand Name:

WXING

Application:

medical devices

Performance:

High Running Performance

Feature:

Interchangeable

Stocks:

customerised

Linear bearings are linear motion systems used for linear strokes in conjunction with cylindrical shafts. Since the bearing ball is in contact with the bearing shell, the steel ball rolls with the minimum frictional resistance. Therefore, the linear bearing has small friction and is relatively stable, and does not change with the bearing speed, and can obtain a smooth linear motion with high sensitivity and high precision. Linear bearing consumption also has its limitations. The most important thing is that the bearing impact load capacity is poor, and the bearing capacity is also poor. Secondly, the linear bearing has large vibration and noise during high-speed motion. Linear bearing quick and easy automatic selection is included. Linear bearings are widely used in sliding parts of industrial machinery such as precision machine tools, textile machinery, food packaging machinery, and printing machinery.

Since the carrier ball is in contact with the bearing point, the load used is small. The steel ball rotates with a very small frictional resistance, so that high-precision smooth motion can be obtained.

Linear bearings are used in conjunction with hardened linear drive shafts. A system for infinite linear motion. The load ball and the quenching drive shaft have a small allowable load because of point contact, but the frictional resistance is the smallest, the precision is high, and the movement is quick.

Application

Linear bearings are increasingly used in precision equipment such as electronic equipment, food machinery, packaging machinery, medical machinery, printing machinery, textile machinery, machinery, instruments, robots, tool machinery, CNC machine tools, automobiles and digital three-dimensional coordinate measuring equipment. Or in the special machinery industry.

Copyright © 2019 Zhejiang waxing electromechanical co.LTD. | All Rights Reserved Design

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.