Quick Details

Type:

Needle

Bore Size:

5 - 30 mm

Applicable Industries:

Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Advertising Company

Brand Name:

WXING OR OEM

Model Number:

KRV30PP

Seals Type:

OPEN/ZZ/2RS

Number of Row:

Single Row

Place of Origin:

Shandong, China

bearing model number:

KRV30PP

Product name:

Printing Machine Bearing CF12 KR30 KRV30PP Cam Follower

Structure:

CURVE ROLLERS

Series:

KR KRV CF

Application:

printing machinery,pressing lines, indexing equipment,

Sample:

Avaliable

Material:

Chrome steel, Carbon steel

Service:

OEM Customized Services

Vibration level:

V1 V2 V3 V4

Noise Level:

Z1,Z2,Z3,Z4

Product feature:

Instead of an inner ring, cam followers have a solid stud (pin) that is threaded so that the cam follower can be quickly and easily attached to appropriate machine components by means of a hexagonal nut.

All three cam follower designs have the same main dimensions. The differences are in their internal design, which make them suitable for various operating conditions. In contrast to ball and roller bearings, where the bearing size refers to the bore diameter d, for cam followers the size refers to their outside diameter D.

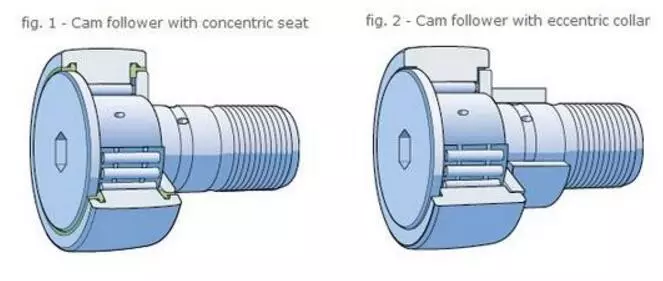

All designs are available with a concentric seat (fig. 1) or an eccentric collar (fig. 2) on the stud. An eccentric collar, which has a shrink-fit onto the stud, enables less stringent positioning tolerances to be specified for associated components. The values for the adjustable eccentricity are listed in the product tables. An eccentric collar is identified by the letter E at the end of the basic designation.

Stud type track roller (cam follower) - KR

- crowned OD

- cylindrical OD is avaible , suffix " X "

- hex wrench socket in stud head

- full needle rollers design is also available ( prefix " KRV " )

- stainless steel 440C is also available ( prefix " SS " )

- two shields is also avaialbe ( suffix " PP " )

Cam follower needle track roller bearing Wheel and pin bearing needle bearing

Application of cam followers:

Escalator;Moving sidewalk;Elevator;Conveyor system;Lifting machinery;Automotive line machinery;Material handling equipments;Linear motion guidance equipments;Cam drives;Screw drives;

Copyright © 2019 Zhejiang waxing electromechanical co.LTD. | All Rights Reserved Design

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.