| Applicable Industries: | Manufacturing Plant, Machinery Repair Shops, Retail | Place of Origin: | SHANDONG |

| Brand Name: | WXING | Model Number: | 8mm |

| Material: | Stainless Steel | Application: | Bearing Accessories |

| Size: | 4.5mm 5mm | Grade: | G10-G1000 |

| Hardness: | 58-62 HRC | Feature: | Stable Performance |

| Certifications: | ISO9001:2008 | Package: | Plastic Bag + Cardboard Box + Wooden |

Product Description

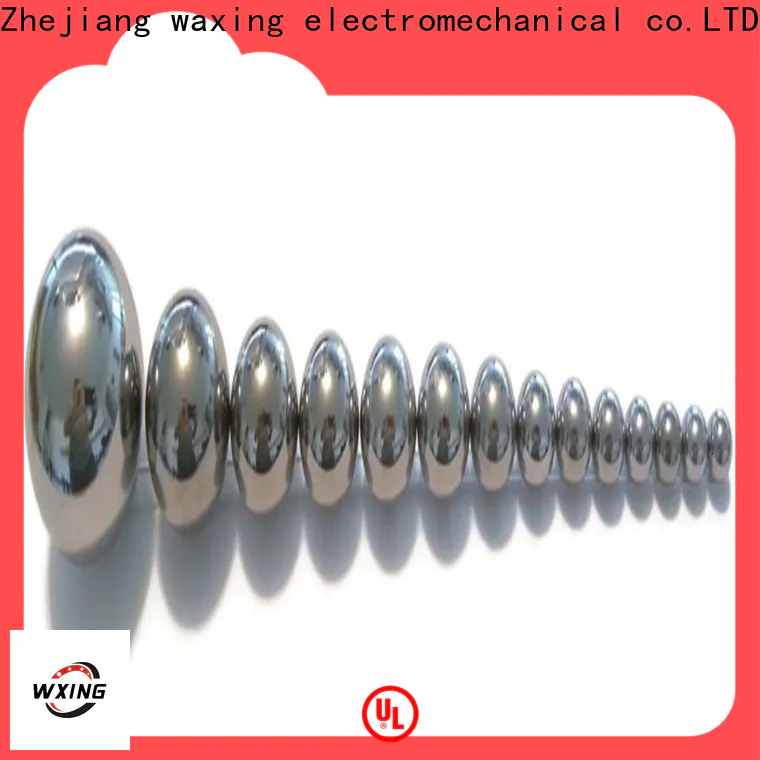

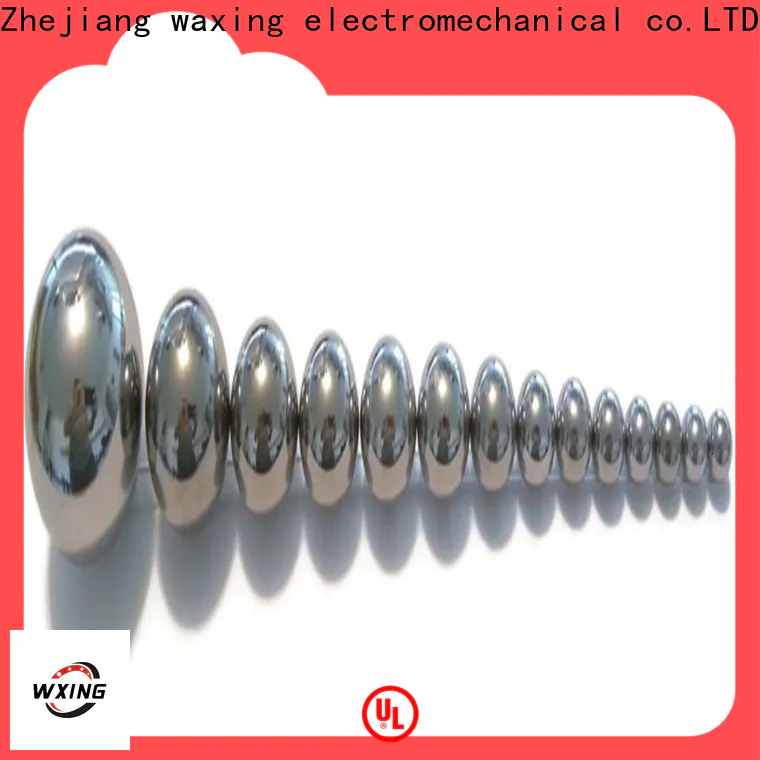

Rich stock best selling full ceramic balls G5 G10 G20 G40 without magnetic

Steel ball according to the production and processing technology is divided into grinding steel ball, forging steel ball, casting steel ball.According to the processing materials are divided into bearing steel ball, stainless steel ball, carbon steel ball, copper bearing steel ball and alloy ball.

Rich stock best selling full ceramic balls G5 G10 G20 G40 without magnetic

Bearing steel ball in the precision bearing industry and the field of life has a long history of use, use more widely, it can be said that most of the rotating place has the existence of steel ball, commonly known as ball, ball.Steel ball is the general name of steel ball, steel segment and special-shaped grinding body.

Specification

Rich stock best selling full ceramic balls G5 G10 G20 G40 without magnetic

Production process:The post-production process of steel ball, namely, automatic cleaning of steel ball, automatic appearance inspection (automatic elimination of unqualified products), automatic rust prevention, counting and packaging, are the key to affect the quality of steel ball.The appearance inspection of steel ball is an indispensable process in the process of steel ball processing.Steel ball appearance inspection mainly includes surface scratch, rust, surface spots and other aspects of detection.Production process of steel ball: stamping -- light grinding -- quenching -- hard grinding -- appearance -- fine grinding -- cleaning -- anti-rust -- finished product packaging.

Application:Steel ball is an important basic component, especially precision industrial steel ball plays an important role in the development of national economy. Steel ball is widely used in bearing, hardware, electronics, tieyi, mechanical equipment, electric power, mining, metallurgy and other fields

Copyright © 2019 Zhejiang waxing electromechanical co.LTD. | All Rights Reserved Design

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.