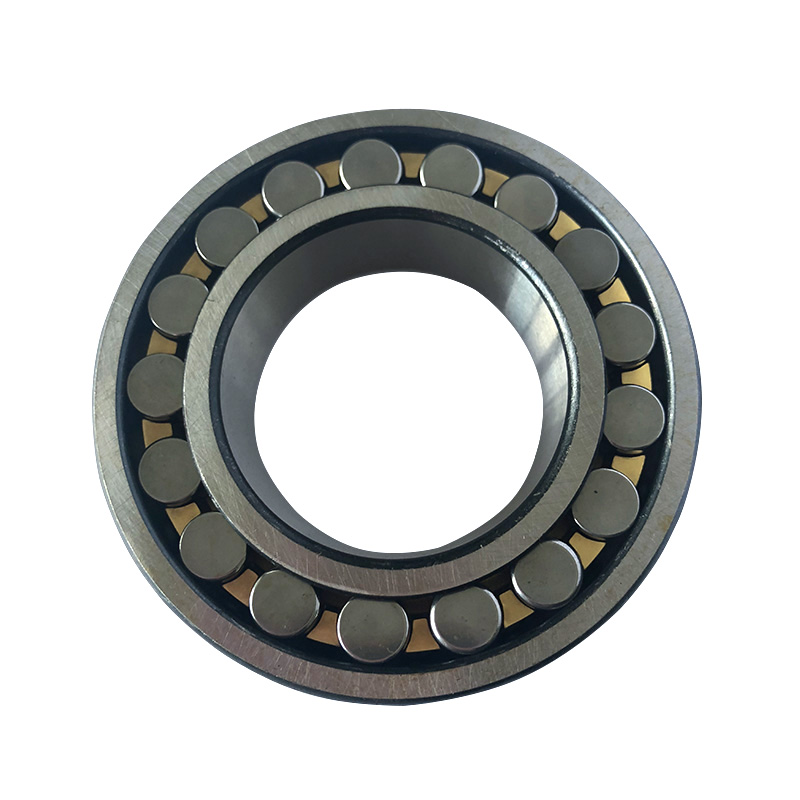

Spherical roller bearing

Spherical Roller Bearings

Understanding the Basics of Spherical Roller Bearings

Spherical roller bearings (SRB) are popular because they can take very heavy loads and are self aligning. Their design allows them to take combined loads in both the radial and axial direction acting together. Each roller is loosely retained in place within a cage that goes full circle between the raceways. Figure 1 shows a simplified drawing of a spherical roller bearing on a shaft under deflection.

The shape of the rolling elements gives the bearings their name. The contact surface is the curved portion of a sphere and the curvature allows the carrying of axial loads. The axial load carrying capacity is less than that of an angular contact bearing but unlike angular contact bearings (unless paired back-to-back or face-to-face), SRB’s can take axial loads in both directions.

SRB’s permit misalignment between the inner and outer races. The bearing takes up the misalignment by allowing the rollers to pivot in the raceways. Because the bearing races can rock independently SRB’s cannot resist a moment load (a load that is acting to tilt or snap the shaft). Double row angular contact or taper roller bearing can be used in such situations.

Misalignment can arise from the operating load causing bending, it can also arise when bearing housings are not machined at a single setting and from the self-load of a shaft and attached components if bearings are mounted far apart. The fact they are forgiving of slight alignment errors makes them a good selection for equipment expected to experience vibration.

For vibrating machinery (e.g. vibrating screens) the bearings are provided with an extra guide ring that runs between the rollers along their inside ends and keeps them square to the race. This center guide increases the bearings working life by reducing roller chattering on the raceways.

The bearings come with factory set internal clearances and no preload is required. Preload is the purposeful application of a force on the bearing to insure the rollers a properly contacting the raceways. Because the clearances are factory set it is important to select the right bearing clearance for the application – especially where the bearing runs hot.

Insuring bearings are well lubricated is always a critical requirement. SRB’s can be lubricated by grease or by oil. In difficult service they will need extra attention to insure the lubrication is actually getting into the running area. To accommodate this, the larger sized bearings from the quality bearing manufacturers have a grease groove machined into the outside of the outer race with several grease holes through the race into the running area. Insure the bearing housing grease nipples are located directly over the grease groove.

If the bearing is oil lubricated in an oil bath insure the oil level always contacts the lowest roller as it comes around so the roller can splash lubricate its fellow rollers and the raceways. Do not over fill the oil bath because when the rollers come around they will have to force their way through the oil and this causes additional heat. The oil level should be no higher than midway up the most bottom roller as it comes around the raceways.

To insure the rolling elements will actually rotate as they come into the loading zone of the bearing there must be a sufficient minimum load. Since SRB’s cannot be preloaded the load must come from the shaft and the attached components. The bearing supplier can perform calculations to confirm the in-service bearing load. If the self-load is insufficient then an extra radial load will need to be applied. This can be by increasing belt or chain tension or purposely increasing the torque on the shaft.

Copyright © 2019 Zhejiang waxing electromechanical co.LTD. | All Rights Reserved Design

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.